Gautam Adani’s $1.2 billion copper smelter in Gujarat—one of India’s most ambitious metal-processing projects—is facing a severe shortage of raw materials, leaving the plant running far below its designed capacity. Despite plans to double output in the next four years, the facility is currently unable to secure even a fraction of the copper concentrate required.

Severe Shortage Hits Adani’s Kutch Copper Plant

According to a Bloomberg report, the smelter has an annual capacity of 500,000 tonnes, but its operations have been crippled by a global squeeze in copper supply. Kutch Copper Ltd., which began production in June, has received less than one-tenth of the raw materials needed to run at full capacity.

Customs data shows that by October, the company had imported only 147,000 tonnes of copper concentrate. In contrast, Hindalco Industries purchased slightly over 1 million tonnes during the same period. For full-scale functioning, the Adani smelter requires nearly 1.6 million tonnes of concentrate annually.

Adani Group has not commented on the supply constraints.

Global Mining Disruptions Add to the Crisis

Copper supply chains worldwide have been rattled by disruptions at major mines owned by companies such as Freeport-McMoRan Inc., Hudbay Minerals Inc., Ivanhoe Mines, and Chile’s state-run Codelco. Simultaneously, China has expanded its smelting capacity, squeezing profit margins for other smelter operators.

As a result, treatment and refining charges have hit record lows, reflecting the extent of the global raw material crunch. Smelters are now being forced to accept minimal margins just to secure concentrate.

Lower Profits and Rising Costs

Kutch Copper plans to double its capacity to 1 million tonnes within four years. But the shortage means it will face rising operational costs and a slower path to reaching full capacity. Bloomberg Intelligence analyst Grant Sporre noted that while the Adani smelter is technically more efficient than many older plants, it may still incur losses in its initial phase.

Where Is the Supply Coming From?

Customs data indicates that BHP Group supplied around 4,700 tonnes of concentrate to the plant, while additional shipments came from Glencore PLC and Hudbay.

The slow ramp-up underscores the broader challenge India faces in achieving self-sufficiency in metals. Demand from infrastructure, power, and construction sectors is surging, but domestic resources remain limited.

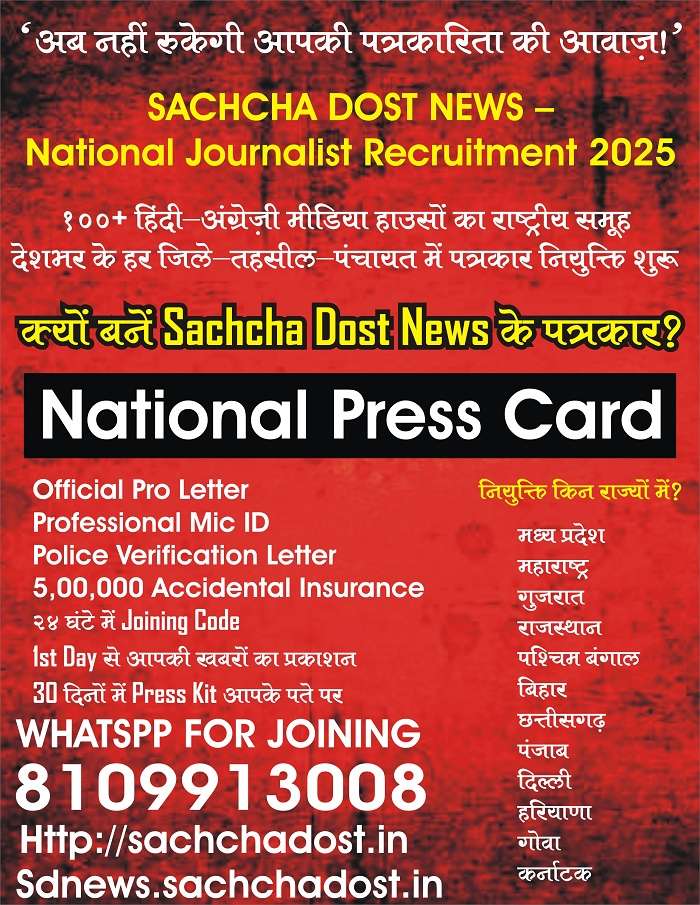

Discover more from SD NEWS agency

Subscribe to get the latest posts sent to your email.